Description

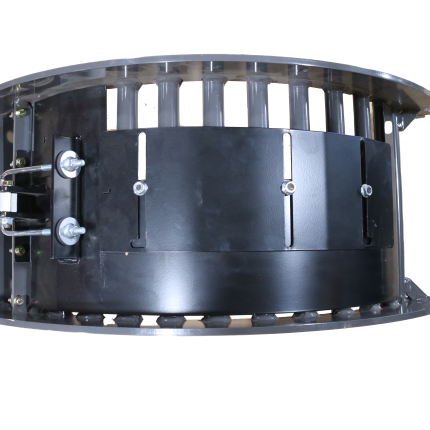

JD STS/S Full Set- No Disruptors

The Copperhead Concave System is a multifaceted, high performance combine concave.

The Copperhead Concave System has four unique features that work together to improve overall performance of your John Deere, Case IH, or Fendt rotor combine:

A patented 90° notch in the round bar.

Progressive bar spacing.

Crop disruptors.

Adjustable cover plates.

All of these work together to create an incredible high-performance multi-crop system.

The Patented 90° notch

The critical importance of 90° notch is easy to grasp when you understand what concaves are supposed to do – THRESH GRAIN. A large wire concave threshes more effectively than a round bar, but a round bar unloads better than a large wire can. Choosing between a wire or round bar concave always means sacrificing something.

With the Copperhead Concave System’s 90° notched round bar, we have captured the ability to do both. It threshes effectively like a large wire concave, and unloads efficiently like a round bar concave. grain quality is dramatically improved because threshing so effectively means we’re able to slow the rotor speed. Slower rotor speed means less grain damage, less fuel consumption, less maintenance and greater efficiency.

Progressive Opening

The spaces between the 90° notched round bars open progressively. What this means is the space between bar one and two is the smallest, the space between two and three is a little bigger, and so on until the spacing between the last two bars (19-20) is the largest.

When harvesting high-yielding larger grain crops, operators’ speed is often limited by the concaves unloading most of the grain on the front right section of the sieves. The Copperhead Concave System overcomes this by spreading the grain more evenly over the sieves. This allows the operator to use their combine more efficiently, thus increasing the ground speed of the combine. Just as we use the notched bars to slow the rotor down, we can use the progressive spacing to speed the harvester up. The machine is able to harvest more acres with the same or lower fuel consumption than before.

Disruptors

The Copperhead Concave System was designed from back to front, starting with the disruptors. These were designed to prevent grain getting carried out the back of the combine in the crop mat. Our disruptors are bolt-in lugs located in the separator grates that can be adjusted to the variance in rotor placement. The primary job of the disruptors, true to their name, is to ‘disrupt’ or stir the crop mat to loosen and free any remaining grain that may be stuck between stocks, stems, leaves or pods.

Adjustable Cover Plates

How do all of these things come together to create the ultimate multi-crop universal concave? Cover plates.

The system comes with three-six adjustable cover plates. These are secured by locking around the top notched bar and a turnbuckle or cam over latch on the bottom for easy installation.

Each cover plate is adjustable from 50% to 100% closed depending on crop conditions. The cover plates hold the mat up to allow additional threshing time and more grain on grain contact.

Durability & Quality

We at Copperhead know that the concave system is a great system; but, we also know it’s a major investment. The concave system is built to be innovative and give the highest performance, but it’s also built it to last.

The Copperhead Concave System has hard surfacing on each of the 90° notched bars to last 2-3000 separating hours. The notched round bar used in the Copperhead Concave System is a 1 inch bar. Traditional round bar concaves only 5/8″ thickness. The caging is ‘overbuilt’ in the same way.

Conclusion

Copperhead Concave System was designed by people who looked at current options and knew there was a better way to thresh grain. With the benefit of a 90 degree threshing edge, a progressive opening, and hard surfacing on heavy built bars, you will see a huge increase in the performance of your machine.

Reviews

There are no reviews yet.